The “alchemy” of sustainability

Associate Professor Sakai turns vegetables and fruit waste into strong building materials that can be eaten in emergencies

As environmental concerns mount around the world, sustainable development has changed from just wishful thinking to an absolute necessity. Associate Professor Yuya Sakai of the Institute of Industrial Science, the University of Tokyo (UTokyo-IIS), is on a mission to develop technologies that make eco-friendly construction a practical and economically viable option. In particular, Sakai has been harnessing a modern-day “alchemy” that turns food waste and inedible food parts into construction materials that are stronger than concrete.

In mid-2020, Associate Professor Yuya Sakai, a specialist in sustainable construction materials at UTokyo-IIS’s Department of Human and Social Systems, heard some jaw-dropping research results: A new material made of Chinese cabbage had a bending strength four times greater than that of concrete.

The unexpected – but welcome and groundbreaking – findings were reported to Sakai by one of his undergraduate students, Kota Machida, who was doing experiments that involved making construction materials from various edible and inedible food items. Machida also was thrilled that the experiments conducted under Sakai’s guidance had produced such stunning results.

“Initially, I thought we could make lumps from these materials, but I never imagined they would be so strong,” Sakai said. “That was the moment when I became confident that we can make value-added, strong construction materials out of food waste.”

This new technology could help reduce Japan’s food waste, which has become a growing social problem in recent years. According to the Environment Ministry, Japan produced about 6 million tons of food waste – edible but discarded for one reason or another – in 2018. The nation also threw away about 19 million tons of “inedible” food items such as skins, outer leaves, damaged crops or “non-standard” farm products that are too big, too small or are not of the desired appearance. Most end up being used for fertilizer and animal feed, or get incinerated or buried as rubbish.

Another huge advantage of these raw materials is that acquiring them will not break the bank. They often can be procured at no cost, and, in some cases, a small fee is paid to anyone who takes them away, Sakai said.

Temperature key to making strong materials

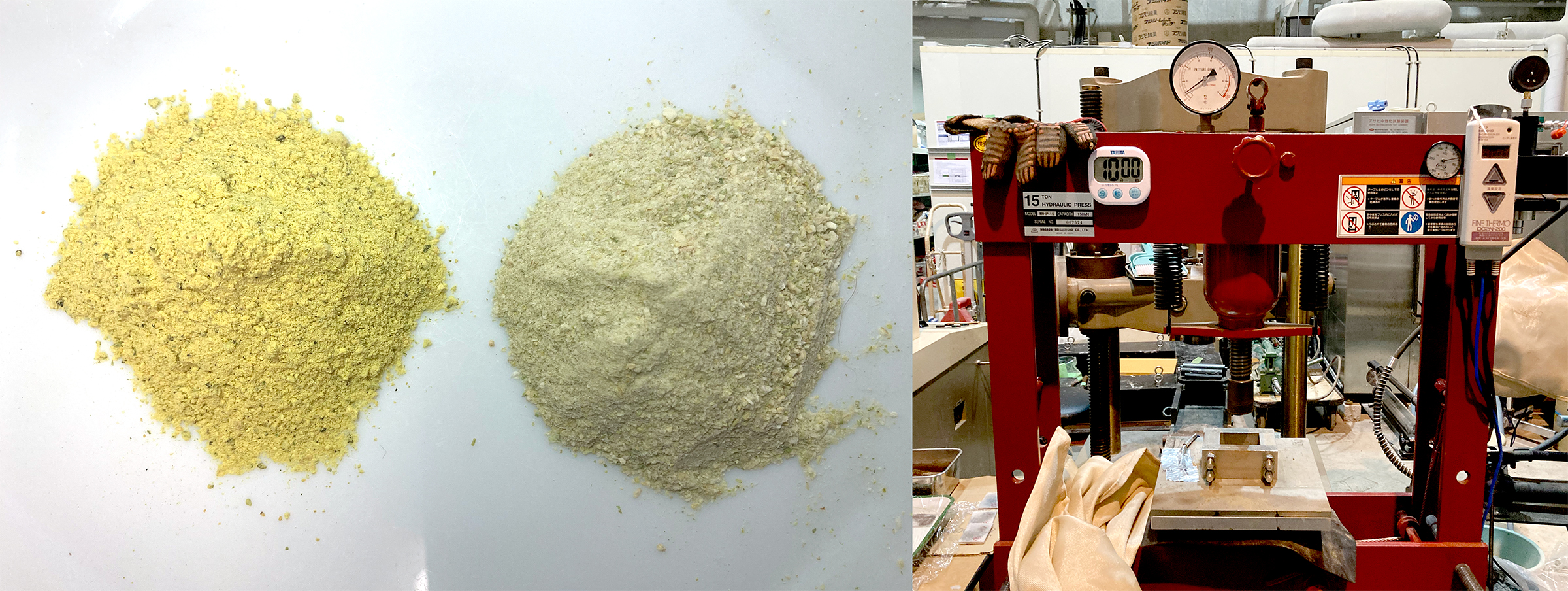

Under the method Sakai’s team developed, which is patent pending, vegetables and fruits are dried, turned into powder and then subject to thermal compression. The materials retain some of the food’s aroma and taste.

Pinpointing the right temperature was the first major hurdle. “We first heated powdered foods, such as tea leaves, to 200℃, but they ended up burning or going mushy,” Sakai said. “After realizing that we must apply the optimal temperature to each specific food item, the research went smoothly.”

The temperatures applied vary, but average around 100℃. This process does not emit a lot of carbon dioxide (CO2). Pressure applied to the mix is about 20 MPa, equivalent to the pressure 2,000 meters under the sea.

The acquired bending strength also depends on the ingredients. Material made of Chinese cabbage yielded the greatest strength, while one made of pumpkin was weak. Adding Chinese cabbage to pumpkin increased the strength, Sakai added.

Just why this process creates such strong materials remains under study, but Sakai hypothesizes that sugar in the food is softened by the heat, flows into gaps among the fine powder particles during compression and then serves as an adhesive when cooled. A material made of Chinese cabbage could withstand 18 MPa, far more than concrete’s about 5 MPa.

The research results raised hope that such materials could replace some, if not all, concrete used for construction at a time when its ingredients such as sand, gravel or crushed stones are in short supply. Cement, an adhesive for concrete’s ingredients, is made from, among others, limestone that must be heated to as high as 1,500℃ to burn. This process requires CO2-emitting energy and also releases this gas from the limestone. In fact, CO2 emissions from cement manufacturing account for a staggering 8 percent of global emissions.

Building materials developed by Sakai’s research team

Credit: Yuya Sakai Laboratory

Making construction materials edible

Another astonishing aspect of these materials is that they are edible. According to Sakai, however, eating building materials is nothing new in Japan. “For example, Kumamoto Castle is known for using some edible construction materials,” Sakai said. This castle built centuries ago in the southern prefecture of Kumamoto reportedly used taro stalks for tatami mats and included dried gourd shavings for wall materials to provide food when it was under siege.

The team has verified that seasonings such as sugar, salt and powdered broth boost the overall strength. The materials can also be used to make accessories, tableware and furniture, to name but a few. “They can be used to make plates,” Sakai said. “You could eat a meal and the plate, too.”

Enhancing the materials’ durability is the next task. Sakai’s team is conducting experiments with edible waterproofing agents after confirming conventional agents used for wood work well but are not edible.

Since the new materials were unveiled in May 2021, Sakai’s team has received suggestions to try various food items, including seaweed, crab shells and mushroom. “People send us all kinds of food waste to include in our experiments,” Sakai said. “We are hoping to make good materials that combine various kinds of food waste.”

Drying: Dried vegetable and fruit waste

Credit: Yuya Sakai Laboratory

Making powder: Pulverized vegetable and fruit waste, Molding: Heat-pressing machine

Credit: Yuya Sakai Laboratory

Addressing concrete problems

Sakai is involved in several concrete-related research projects. One project focuses on recycling concrete in a sustainable manner. Crushing old concrete structures and compressing the powder can produce new, robust concrete, he said.

Sakai’s research could even have implications that go beyond our planet. Sakai is conducting research to determine whether sand particles, for example those on the moon, could be bonded without using conventional adhesives, such as cement or resins. “If that sand could be held together with alcohol and a catalyst to make construction materials, structures could be built on the moon,” Sakai said.

An avid reader of any genre, Sakai often gets research inspiration from reading books. Sakai also is a father of three small children, and he gets up at 5 a.m. so he has time in the evenings after work to play with and care for them.

Related Article> Food Scraps Get a Bold New Life

Text:J-Proze Yumiko Mori

Comments

No comments yet.

Join by voting

How did you feel about the "Possible Future" depicted in this article? Vote on your expectations!

Please visit the laboratory website if you would like to learn more about this article.

Share