Circulating Metals for Economic Growth While Protecting the Environment

Metal Recycling Technologies to Support Manufacturing

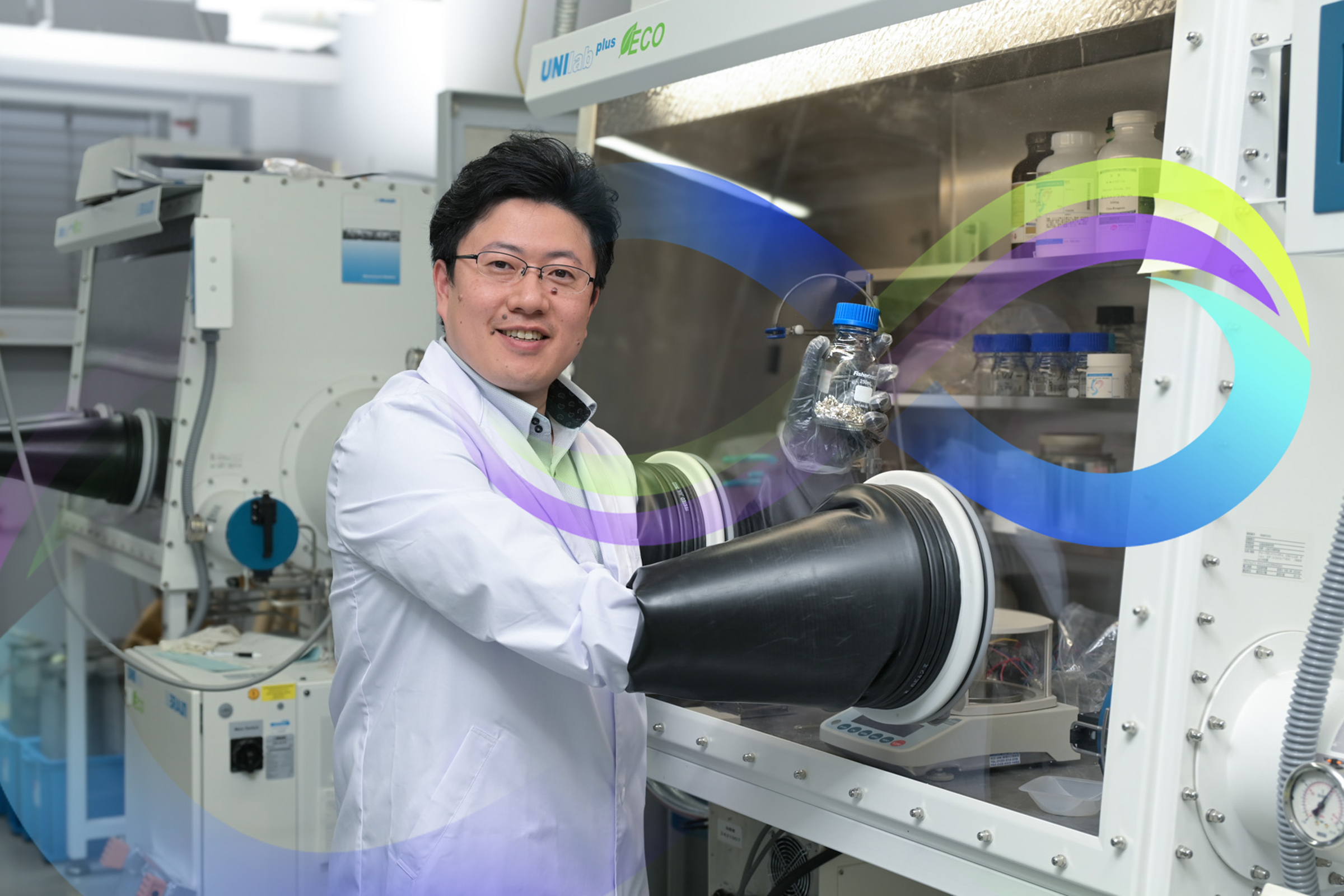

Metallic materials are what support advanced technologies. Precious metals are used in electronic components, automotive exhaust purification catalysts, fuel cells, pharmaceuticals, and medical instruments. These metals are limited in quantity, so recycling is essential, yet this presents its own challenges. The following introduces Takanari Ouchi, a lecturer at the Institute of Industrial Science, The University of Tokyo, who is developing a recycling technology applicable to all metals, including precious metals.

Driven by a desire to end the era of relentless extraction

Recently, usage of the term “rare metals” has become more frequent. There are also other classifications for metals, such as “base metals” and “precious metals.” Base metals such as iron, aluminum, copper, lead, and zinc are produced and consumed in large volumes. In contrast, rare metals are those with high industrial demand yet are limited in quantity or are difficult to mine and refine. Examples of rare earth metals include neodymium used in high-performance motors; lithium, cobalt, and nickel used in batteries; and indium used in liquid crystal displays. Many people associate precious metals with jewelry, and although there is no strictly scientific definition, the term generally refers to chemically stable and highly scarce metals such as gold, silver, and the platinum group metals (platinum, palladium, rhodium, ruthenium, iridium, and osmium).

The extraction of any metal, from mining the ore through to smelting it into a usable form, entails substantial energy consumption and CO2 emissions. “We need to put an end to the era of relentless extraction,” says Takanari Ouchi, a lecturer at the UTokyo-IIS, Research Center for Sustainable Material Energy Integration. “We need to think about how to make the most effective use of every metal once it has been produced.”

“Scrap sorted out and collected for recycling from used or unwanted electrical and electronic components and appliances contains a mixture of various metals, plastics, ceramics, and other materials. Recovering specific metals from among these for reuse entails considerable effort and expense. When it comes to recycling metals other than high-value precious metals, cost remains a particularly major barrier. Breaking through this will require new technologies that go beyond mere extensions of existing methods.”

Research and development of energy-efficient manufacturing and recycling processes for non-ferrous metals, including precious and rare metals.

Japan is on the cutting edge in precious metal recycling. However, …

Precious metals are also extensively used as industrial materials. For instance, platinum group metals are incorporated into automotive exhaust purification catalysts and fuel cells, while gold is used as a coating for wiring and as a contact material in electronic circuits. Precious metals are also used as catalysts in synthesizing a wide range of chemical products, pharmaceuticals, and pesticides. In addition, they can be components in medical test kits and even in pharmaceuticals.

The industrial demand for precious metals is so great that it would be impossible to list all of their applications. However, they are extremely scarce and often only found in specific regions, meaning that supply is constantly at risk.

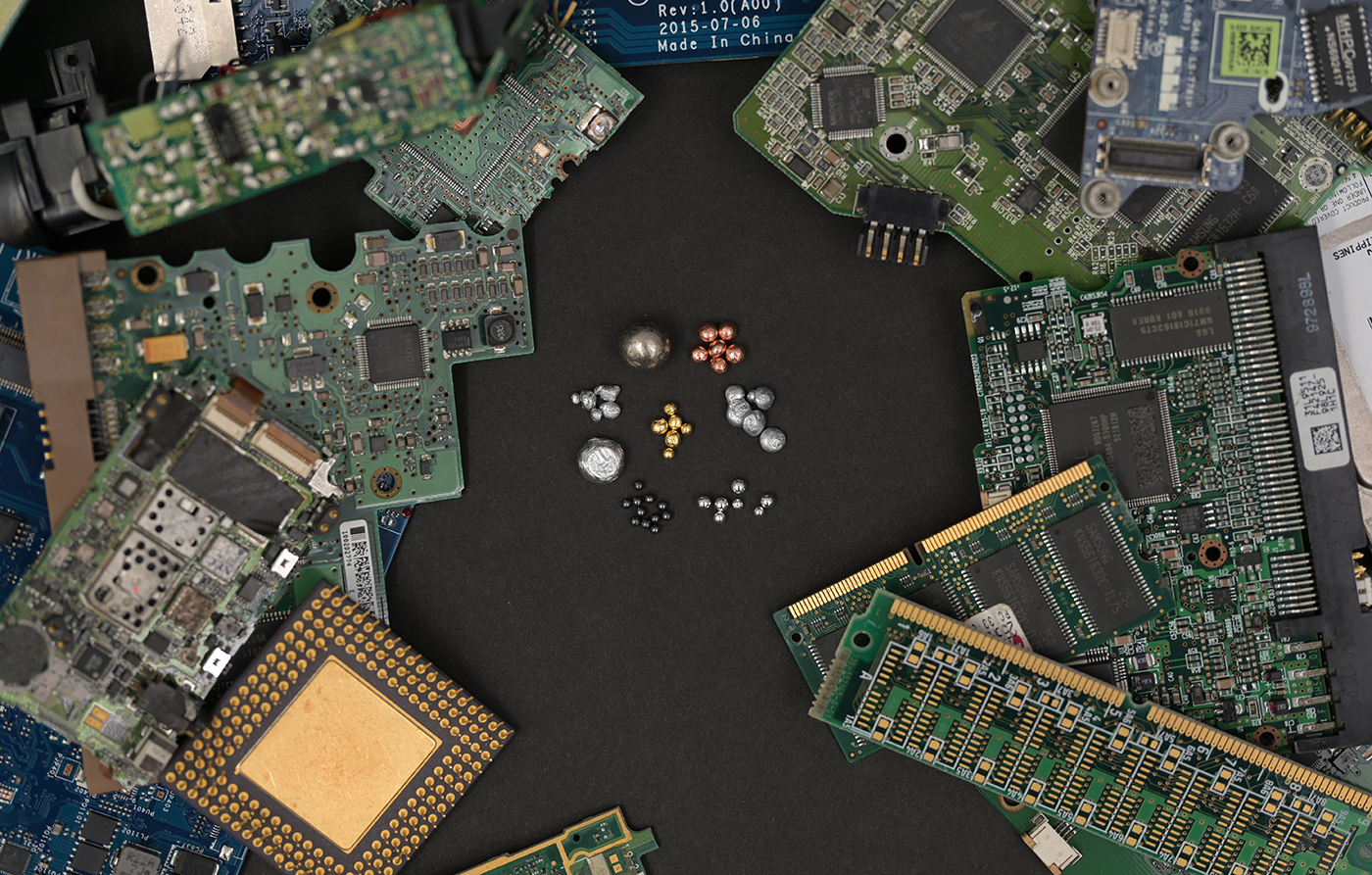

Examples of metals used in electronic circuit boards. Starting from the large particle at the top outer edge and moving clockwise—nickel, copper, aluminum, silver, antimony, zinc, and lead—with gold at the center. Efficient recycling of each of these metals is essential.

For example, South Africa and Russia together account for more than 80% of global platinum production. What’s more, the ore contains only an extremely small amount of the desired precious metal, with around 5 grams of platinum group metals per ton of ore at most and the remainder being “waste.” Mining damages the environment, and the manufacturing process for precious metals requires large amounts of energy and chemicals, making their environmental impact a serious concern.

On the other hand, scrap from automotive exhaust purification catalysts contains platinum group metals in concentrations more than 1,000 times higher than those found in ore. This high concentration greatly reduces the amounts of chemicals and energy needed for refining. Therefore, recycling the precious metals contained in scrap is crucial not only in terms of environmental conservation but also for economic viability. Japan is on the cutting edge in precious metal recycling, gathering automotive exhaust catalysts and electronic circuit boards from around the world for processing.

“Because precious metals are so valuable, they are relatively easy to recycle from a cost standpoint. However, current recycling processes consume vast amounts of energy and produce large volumes of hazardous waste liquids and gases, so it’s necessary to develop new processes,” explains Ouchi. So, what approach is being taken?

Pinpoint extraction of target metals

Ouchi’s goal is to develop a process that selectively extracts and separates only the target metal, maximizing energy efficiency and minimizing both chemical use and waste generation. One example is the pinpoint recovery of gold from scrap.

Gold is chemically stable, which is part of its value, but that very stability makes it difficult to dissolve in chemicals, posing a major challenge when extracting and separating. In contrast, electronic circuit boards contain copper—which is much easier to dissolve than gold—in amounts roughly 1,000 times greater than gold. In addition to copper, electronic circuit boards also contain a variety of other metals such as nickel, aluminum, silver, antimony, zinc, and lead. At present, the standard approach is to dissolve all of these metals into an aqueous solution and, through a complex multi-stage process, extract and separate them to ultimately obtain each metal individually. This method, however, also produces hazardous waste liquids and exhaust gases.

“If we could extract and separate out individual metals—such as gold alone—right from the start, we could greatly reduce energy and chemical consumption, reducing not only costs but also the environmental impact.”

Thus, Ouchi, a specialist in electrochemistry, turned his attention to the metals’ degree of “electronegativity,” a measure of how strongly an atom attracts electrons. Since electrons carry a negative charge, metals that readily attract them—those with high electronegativity—are more easily able to achieve a negative electrical state.

Under the conventional method, dissolving precious metals (M) from scrap into a solvent required removing electrons from the metal to convert it into a positively charged ion state (M⁺). However, precious metals are resistant to this process, requiring the use of strong oxidizing agents or complexing agents.

Ouchi instead proposed taking advantage of their high electronegativity to facilitate dissolving precious metals into a solvent by first converting them into a negatively charged ion state (M−). It is known that metals (M) with high electronegativity can––when in a negatively charged ion state (M−)––dissolve in a suitable solvent when alloyed with a reactive metal (R) of lower electronegativity.

Conceptual diagram of a new process for concentrating and separating precious metals

(Au: Gold, PGMs: Platinum Group Metals / Li: Lithium, Na: Sodium, Ca: Calcium)

Building on this, he proposed a new process: inserting electrodes into molten salt in which precious metals have dissolved as negatively charged ions (M−), then applying voltage to strip electrons from the ions (molten salt electrolysis) to separate out the precious metals (M). Compared with conventional methods, this process involves fewer steps and requires less time. In principle, it generates no waste liquids or exhaust gases, making it a highly efficient and environmentally friendly process with strong potential for practical application.

Manufacturing and resource circulation go hand in hand

Ouchi applies his knowledge of electrochemistry to tackle these difficult challenges, having previously engaged in research on secondary batteries. He recalls being deeply impressed by an idea put forth by the professor he was working under at the time: “If the chemical reactions used in refining technology to remove impurities from metals can be effectively harnessed, they can be used to store energy.”

“In the fields of metal smelting and recycling, energy is regarded as a cost—something consumed to produce the metal product. With respect to batteries, however, the very same reactions can serve to store energy. In other words, the processes of smelting and recycling metals can be seen not only as producing metal, but also as storing energy in the form of metal. Applications of chemical reactions will become limitless only by human ingenuity. I understand that those who pursue chemistry see endless possibilities in designing and creating compounds and materials with new functions, but I am convinced that recovering and recycling them also presents limitless potential.”

Ouchi explains that if manufacturing were seen as society’s “arteries,” then resource circulation would be its “veins.”

“Researchers in this field sometimes describe their work as the ‘veins’ of society—recovering, purifying, and making resources usable again. Just as the human body cannot function without veins, within the overall framework of the planet, manufacturing and resource circulation must also develop together hand in hand.”

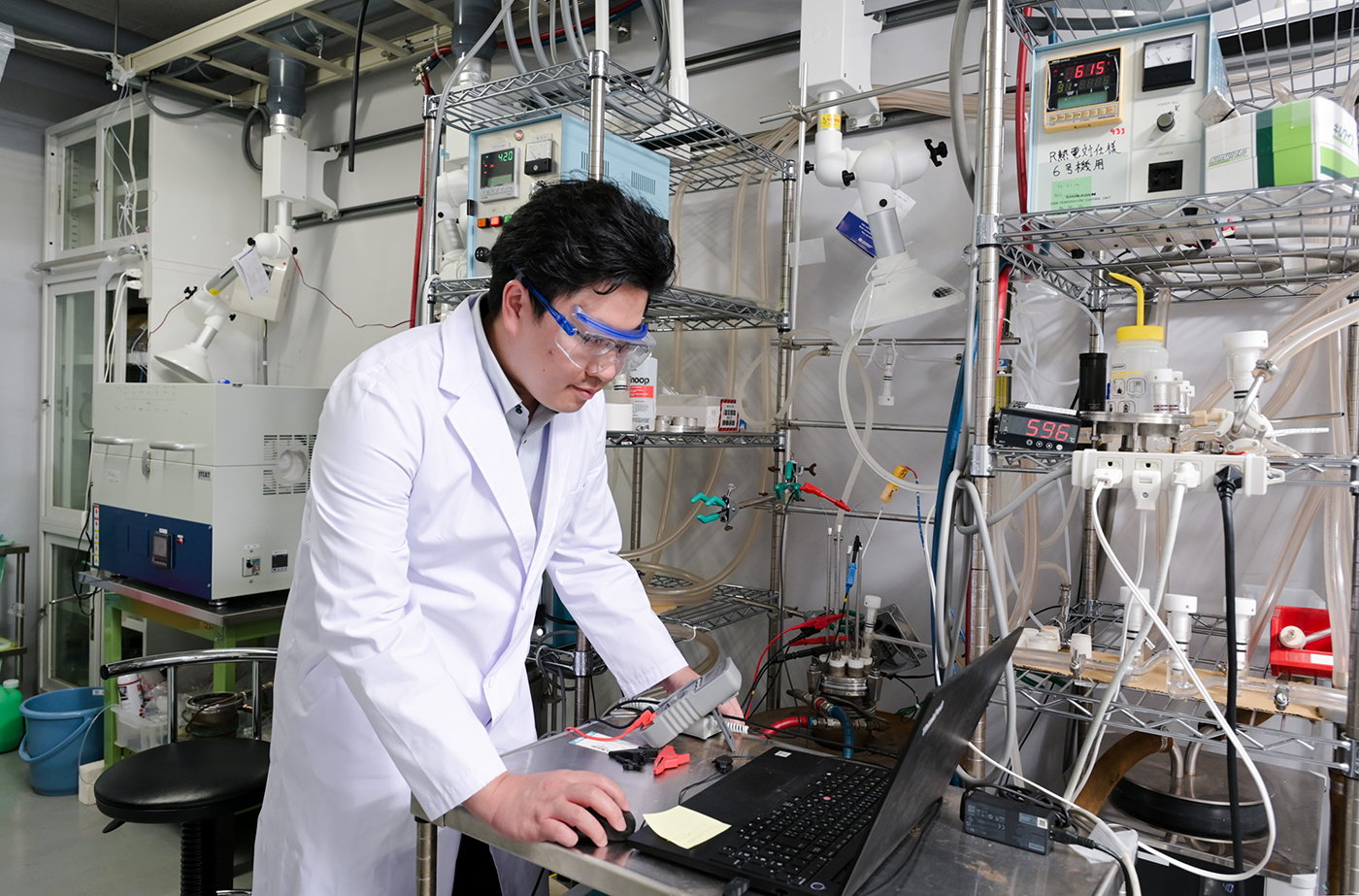

Ouchi and others continue to refine metal recycling technologies on a daily basis in the effort to realize a sustainable society.

In the laboratory, rows of electric furnaces capable of generating high-temperature environments exceeding 1,000 °C are used to melt metals for experimentation.

Featured Researcher

Takanari Ouchi

(Lecturer, Institute of Industrial Science, The University of Tokyo)

Special Field of Study: Physical Chemistry for Energy and Materials

Comments

No comments yet.

Join by voting

How did you feel about the "Possible Future" depicted in this article? Vote on your expectations!

Please visit the laboratory website if you would like to learn more about this article.

Share