PENTA : Pursuing a Nomadic Lifestyle

Researchers at UTokyo-IIS have developed a self-built architectural prototype that is lightweight and easy to construct, using 3D printed (Additive Manufactured: AM) aluminum alloy joints.

Thanks to UTokyo-IIS researchers, a nomadic lifestyle free from mortgages may become a life option.

The researchers have developed a prototype of a house that can be self-assembled without the use of heavy construction equipment. This architecture, offering a balance between the durability of a house and the mobility of a tent, can be freely disassembled and reassembled. The structure’s isometric 60mm-diameter aluminum frame reduces weight, and aluminum alloy joints, fabricated by 3D printing (additive manufacturing), simplify construction, enabling four people to assemble the structure in about two days.

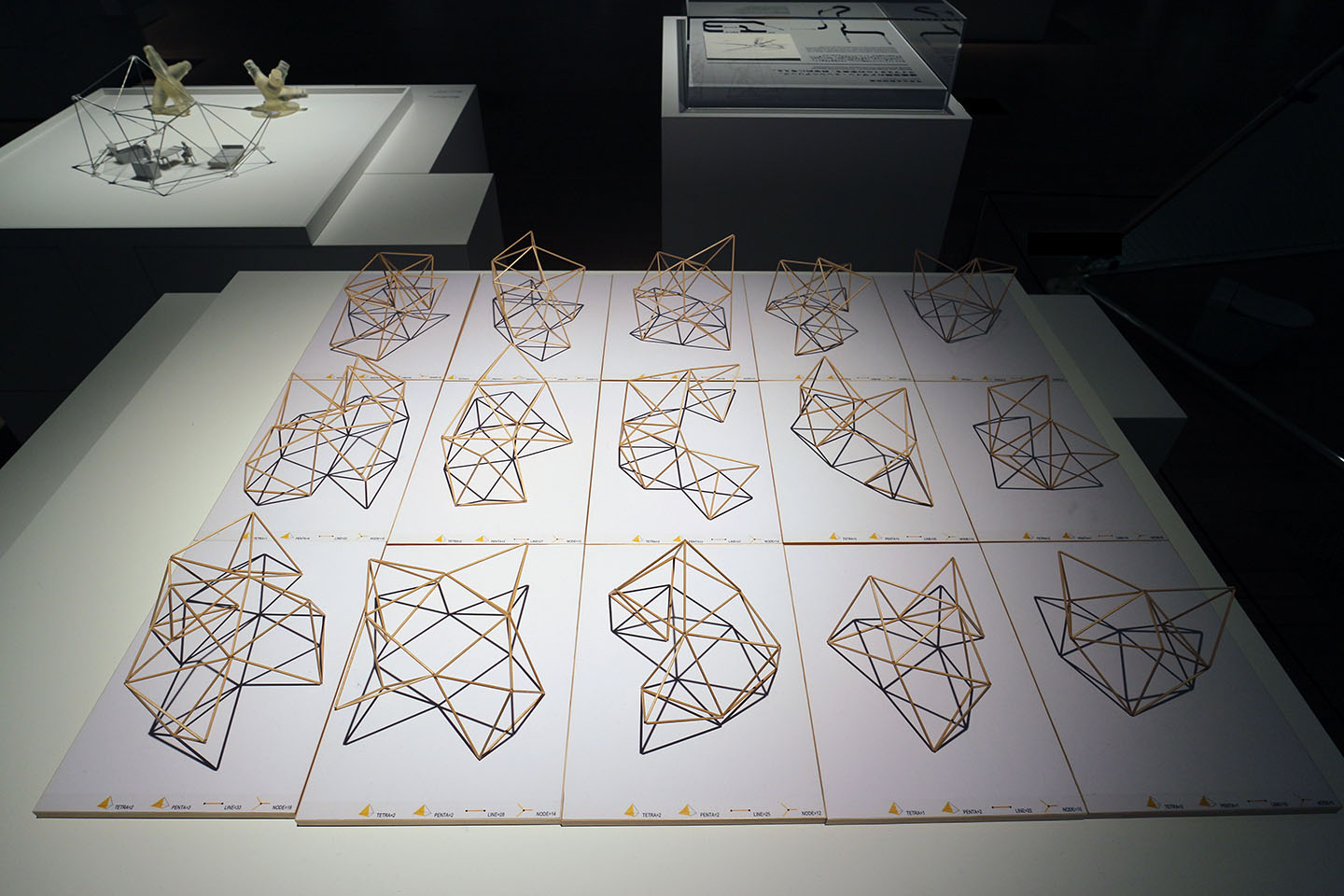

Variant space frame shapes generated by the PENTA system

Photograph: Kotaro Imai Laboratory

Lightweight building frames that can be easily assembled are in demand for disaster recovery housing, hospitals in developing countries, glamping, and many other applications. Prefabricated units are the most common solution, but they have the problem that the unit space is uniform in size, making it difficult to ensure flexibility in planning. Historically, the geodesic dome invented by the American Inventor(Architect) Buckminster Fuller was a prominent example of such a lightweight space frame, but it could only create a spherical space.

The team’s method uses a tetrahedron (structurally advantageous and composed of triangles, similar to the geodesic dome) and a deformable pentahedron with a square base. These can be combined to form a hybrid space frame. Using 3D printing, the angles of the members at the joints can be freely adjusted, allowing for a variety of forms beyond the spherical.

By replacing sets of joints, the overall form can be transformed, allowing the scale to be changed and the shape to be adapted to changing uses and site geometries.

The exterior walls, fitting any external shape of the space frame, can be made from standardized, same-sized equilateral triangular panels, which can be transparent, opaque, or insulated. Attached to the aluminum pipes with gasket rubber, these panels ensure a watertight surface.

Future research aims to enhance the environmental performance of the prototype and possibly lead to the creation of a venture company to market the parts, supporting the vision of a flexible, nomadic lifestyle, free from traditional housing constraints.

Photograph: Project Professor Shunji Yamanaka

Text: Professor Kotaro Imai

This article was originally published in the UTokyo-IIS Bulletin, an English-language magazine that introduces the activities of UTokyo-IIS.

> Publications

Comments

No comments yet.

Join by voting

How did you feel about the "Possible Future" depicted in this article? Vote on your expectations!

Please visit the laboratory website if you would like to learn more about this article.

Share