Cheap yet ultrapure titanium metal might enable widespread use in industry

Researchers led by Professor Toru H. Okabe, have removed nearly all of the oxygen from titanium in a cheap, straightforward protocol. The yttrium side product is easily recycled for subsequent purifications. This work is an important advance in metallurgy that will lower the cost of producing high-purity titanium and in so doing make more efficient use of an abundant, versatile metal.

Titanium is the ninth most abundant element in the Earth’s crust, yet products based on pure titanium are uncommon because it’s expensive to remove the oxygen from titanium ore. Reducing costs would encourage manufacturers to take advantage of the highly useful properties of titanium in their products.

Now, in a study recently published in Nature Communications, researchers from the Institute of Industrial Science, The University of Tokyo, have developed a procedure that reduces the cost of producing titanium that’s almost entirely free of oxygen. This oxygen removal protocol might benefit technological development and environmental sustainability.

Titanium is an incredibly versatile material because not only does it typically resist chemical damage, it’s strong yet light. For example, its light weight compared with other metals is why the base frame of modern iPhones consists of titanium alloy, despite the increased cost. Unfortunately, producing ultrapure titanium is significantly more expensive than manufacturing steel (an iron alloy) and aluminum, owing to the substantial use of energy and resources in preparing high-purity titanium. Developing a cheap, easy way to prepare it—and facilitate product development for industry and common consumers—is the problem the researchers aimed to address.

“Industry mass-produces iron and aluminum metal—but not titanium metal, because of the expense of removing the oxygen from the ore,” explains Toru H. Okabe, lead author of the study. “We use an innovative technology based on rare-earth metals that removes oxygen from titanium to 0.02% on a per-mass basis.”

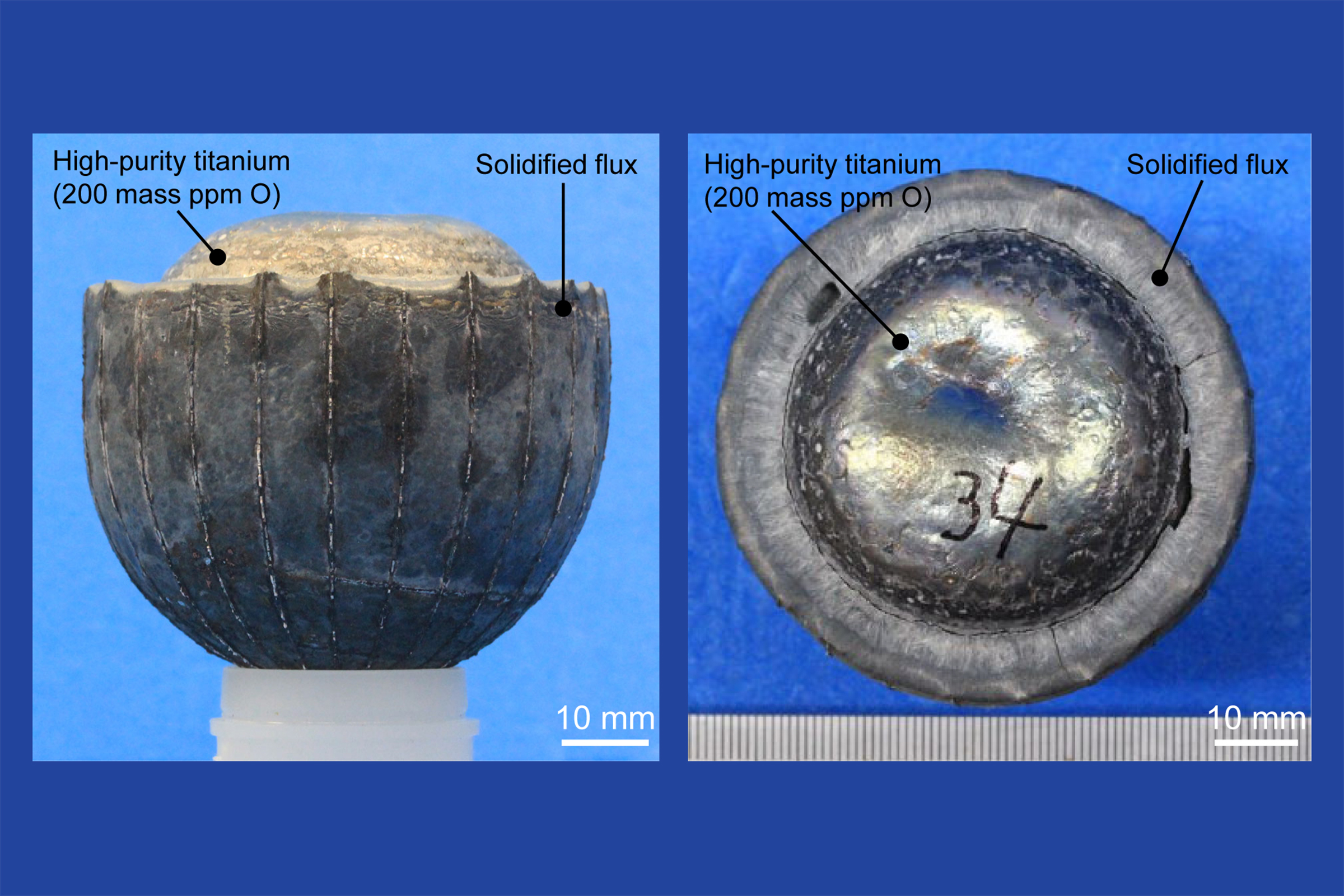

A critical step in the researchers’ protocol is reacting molten titanium with yttrium metal and yttrium trifluoride or a similar substance. The end result is a low-cost, solid, de-oxygenated titanium alloy. The reacted yttrium can be recycled for further use. A highlight of the researchers’ work is that even titanium scrap that contains large amounts of oxygen can be processed in this manner.

“We’re excited by the versatility of our protocol,” says Okabe. “The lack of intermediate compounds and straightforward procedures will facilitate adoption in industry.”

This work is an important step forward in making more efficient use of high-purity titanium than at present. A limitation of this work is that the resulting de-oxygenated titanium contains yttrium, up to 1% by mass; yttrium can influence the mechanical and chemical properties of titanium alloy. After solving the yttrium contamination problem, applications to industrial manufacturing will be straightforward.

The article, “Direct production of low-oxygen-concentration titanium from molten titanium,” was published in Nature Communications at DOI: 10.1038/s41467-024-49085-4

Image: Photographs of a Ti sample after melting and deoxidation using a cold crucible induction melting furnace

Credit: Toru H. Okabe Laboratory

Professor Toru H. Okabe

Comments

No comments yet.

Join by voting

How did you feel about the "Possible Future" depicted in this article? Vote on your expectations!

Please visit the laboratory website if you would like to learn more about this article.

Share